In my last two articles, I had put forward my thoughts on ERP Systems and Business Software application development as a process. Going further, now, I am putting forward my thoughts on 'Business Process Automation in Engineering & Manufacturing Industries'.

Engineering or Manufacturing industry is where actually a process automation was born. Not only for traditional, on-the-floor warehouse workflows but also for the office operations and systems that contribute to quick product lead times and keep a plant running.

Yet it's also an industry, which is facing many hardships as globalization and a cutthroat and stiff competition continues to decrease the bottom lines.

Based on my experience of last 40 years in the field, I feel, Technology is the enabler for business process automation (BPA) in the Engineering industry, and it can automate workflows to the point where human intervention is unnecessary. Automation can save time and money, delight the customers, and preclude human errors.But not every business process in an engineering and manufacturing organization is a good fit for automation.

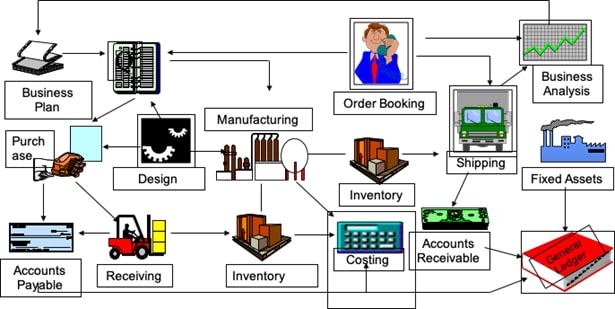

A picture depicting various processes in a complex engineering and manufacturing environment, posted below would give any one, an idea, where the automation can be done in an engineering industry. However, the picture is generic in nature, and only an Expert in the subject matter can help the organizations in deciding this.

There are multiple reasons, as to why one should automate the business processes, but I find, following to be the crucial ones:

COVID-19, also has taught a lesson that, going forward, automation of the processes, and geographical independence in the working environment, would be key in the coming decade, for the organizations to survive.

Targeting the following work areas on priority for Business Process Automation (BPA), would help the organizations, to gear up and be ready for implementing Industry 4.0, Robotic Process Automation, Artificial Intelligence and also against the rising customer expectations

Customer Relationship Management or commonly known as CRM, is also the important process and includes lot of activities. But personally, I feel, CRM should be considered for automation, only after the 'House' is clean and the essential's are in place.

Automation of any of the Business Processes, is a project by itself, and it goes through 4 major phases.

To conclude:

Implementing Business Process automation and workflows is one of the most valuable additions engineering and manufacturing organizations can make during their move to 'Digital Operations or Digitization'.

This stage will help the organizations to improve manufacturing capabilities moving forward, leveraging efficiencies and allowing teams to access the information they need in order to take action. They can do this knowing their decisions are informed by data.

Something about ShriSoft:

We, at ShriSoft, help our engineering and manufacturing clients to analyse, and decide upon which business processes to automate.

ShriSoft starts by looking at the strategic and operating drivers for process improvements in client's organization. Thrust is given by taking into consideration three basic principles: